Sauer System

Sauer System manufactures high-performance tooling for the corrugated box industry and is an affiliate of Sauer Machine Company. Innovation, attention to detail, and uncompromising quality are at the heart of their culture. Adding value by solving problems and being a resource and partner to agents and customers alike provides an invaluable asset to our program.

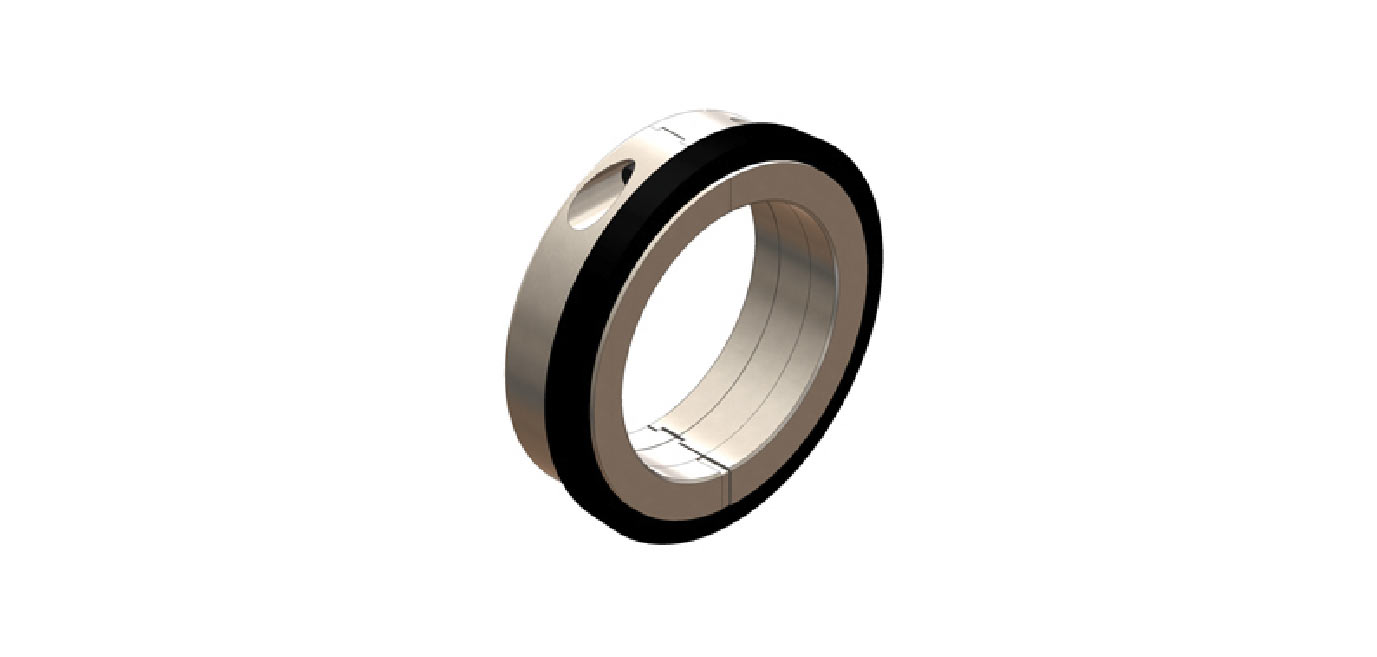

Creasing Heads & Rings

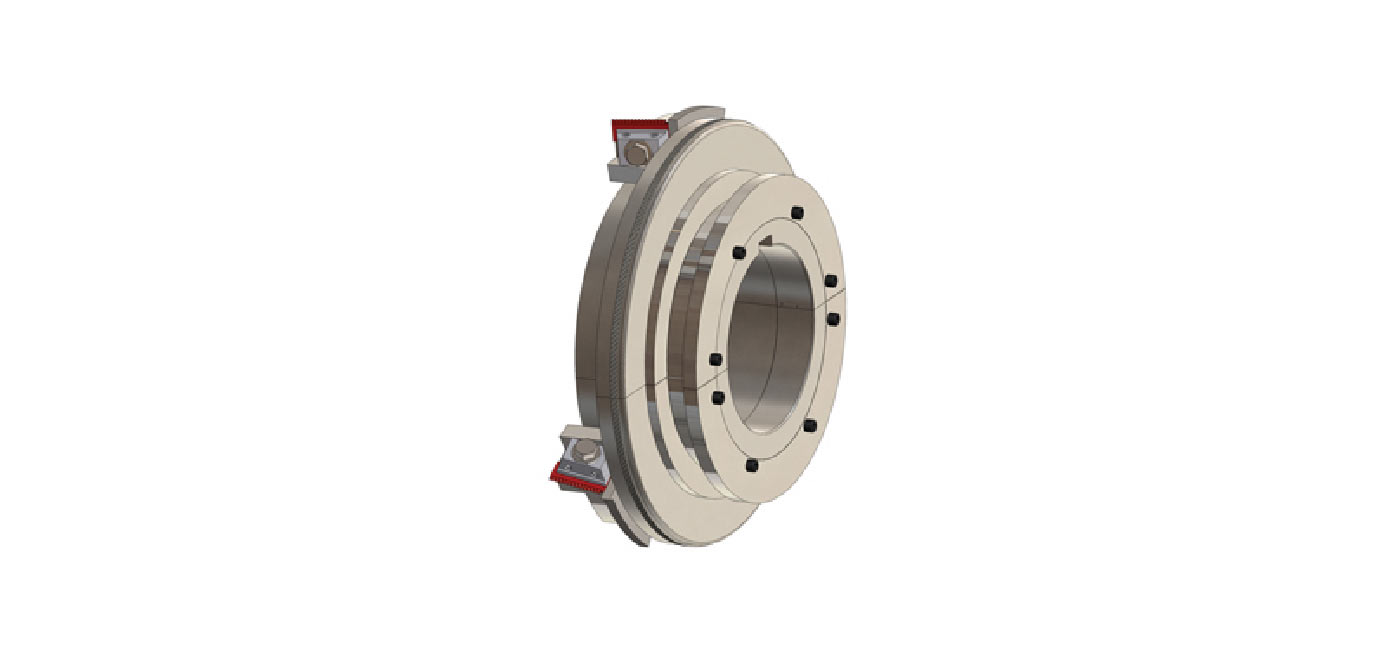

G3 Creasing

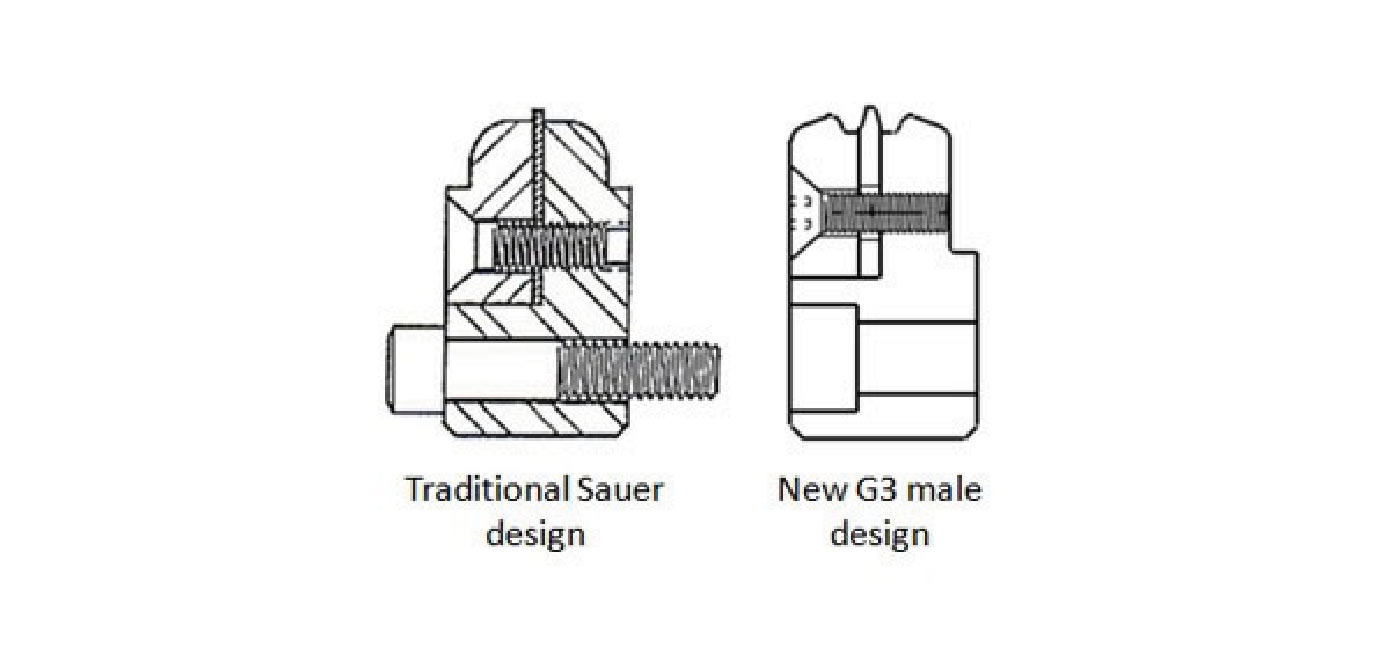

Traditional creasing profiles were designed for a time when board was made from paper containing mainly virgin fibre. Today’s board contains a high percentage of recycled content and is made with lightweight liners. Pairing traditional creasing profiles with recycled board can lead to rolling scores, manufacturer’s gap variation, and trouble achieving a consistent crease line.

The new G3 system was specifically designed to improve creasing and folding when converting recycled board and other challenging materials.

While traditional male profiles force the board to stretch around the insert during creasing, leading to rolling and cracking, the G3 male profile incorporates specific geometry which conditions the board and provides relief for the inside liner. The result is improved folding, a proven reduction in manufacturer’s gap variation and a higher quality finished product.

The system features a replaceable tapered insert, available in various heights depending on the application.

Creasing Tips

Sauer System recommends creasing against 70 durometer or 80 durometer polyurethane for all creasing applications.

When troubleshooting folding and creasing issues, first ensure sheets are being fed correctly through the press. No creasing profile will make up for skewed sheets. To check for skew, collect one or more creased sheets after they have left the slot/score section but before they enter the folding section. Fold them in half along the centre crease line and check to ensure the operator side and drive side edges match up. Not matching up correctly is evidence of a skewing issue.

Ensure the crease lines are being made at the centre of the slots. When running 3/8” slots, the crease line should be centered 3/16” from either side of both the lead and trial slot. If the crease line is offset, the slotter heads and creasing heads should be realigned.

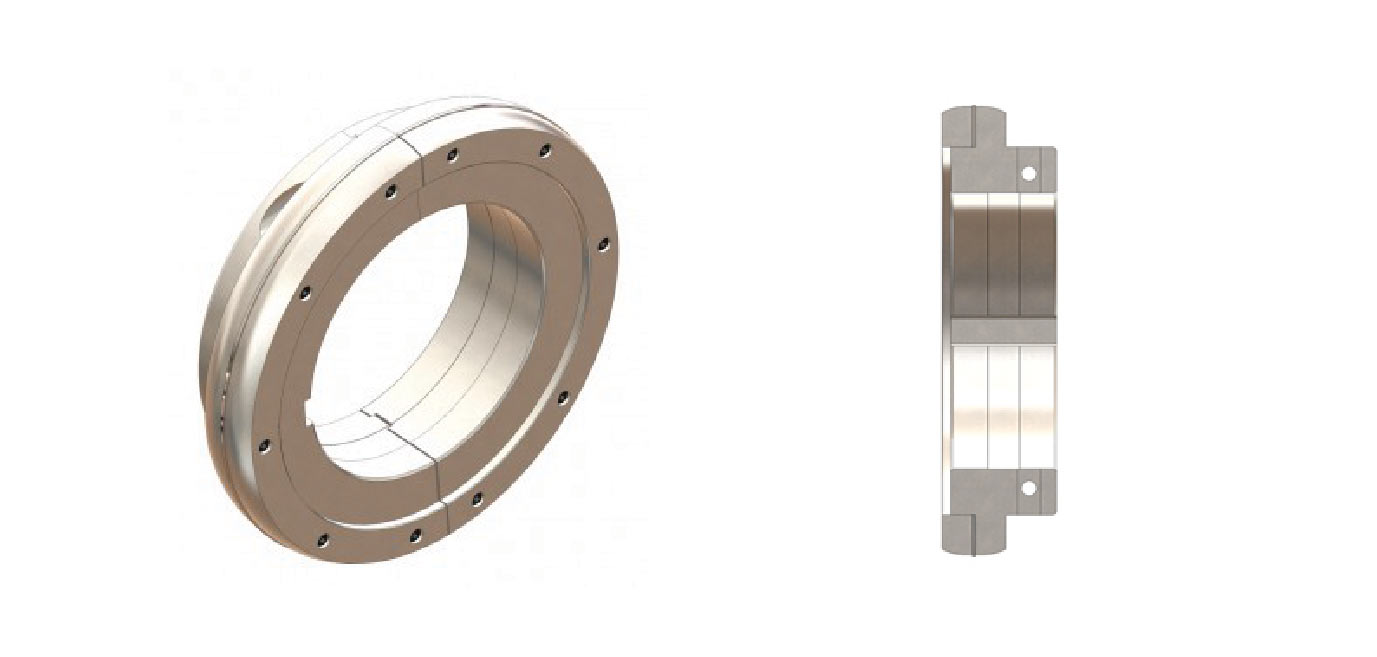

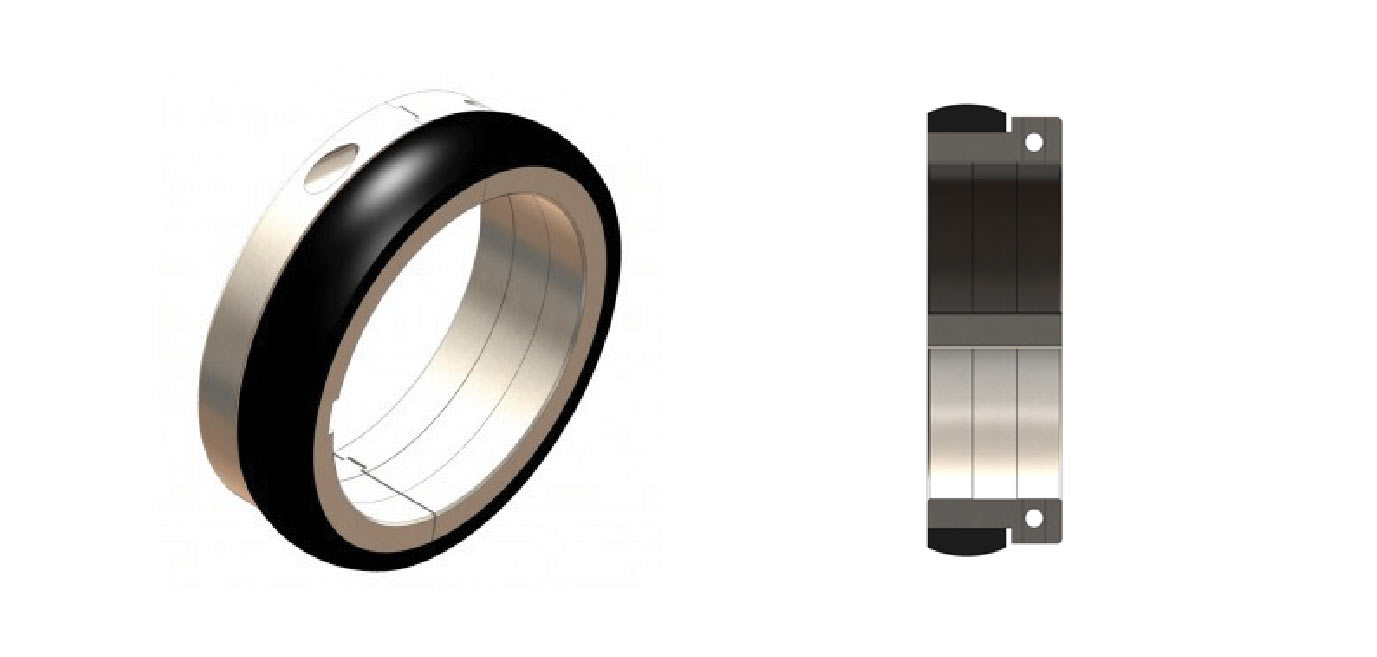

Traditional Creasing

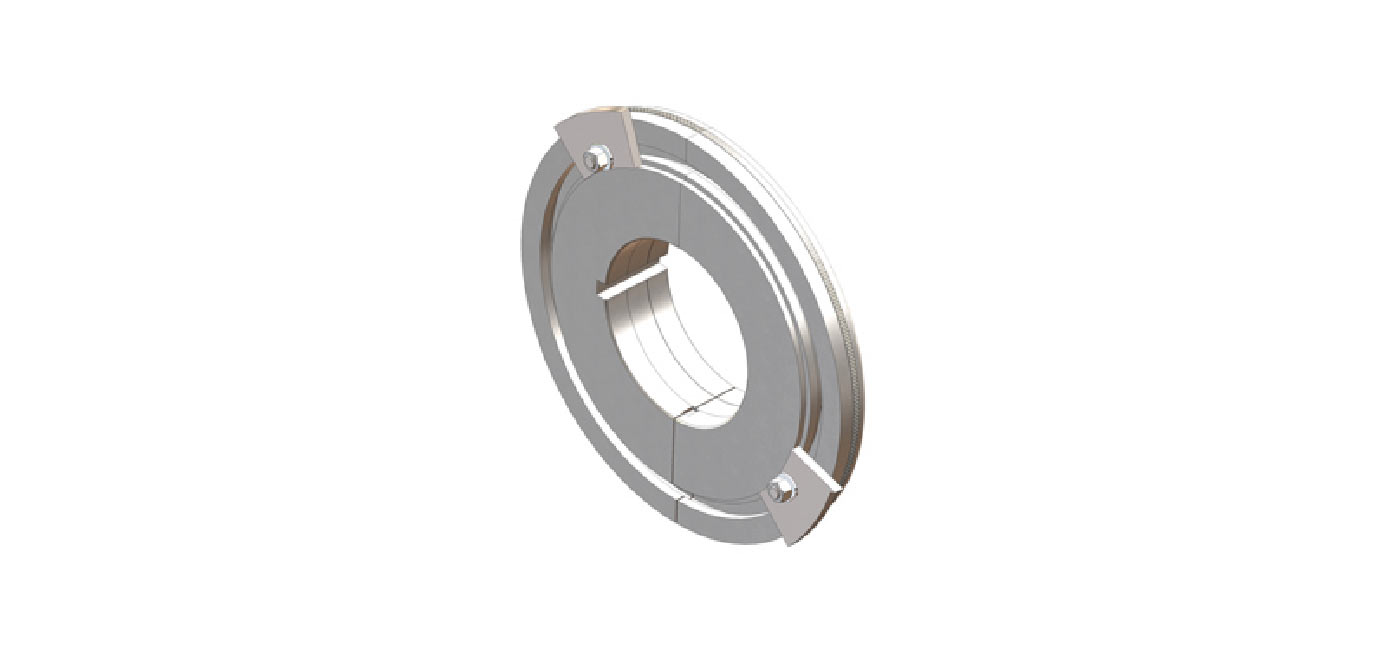

Sauer System continues to manufacture and support the traditional “Sauer style” creasing profile which features a three-piece assembly with a .050” wide replaceable scoring bead available in various heights.

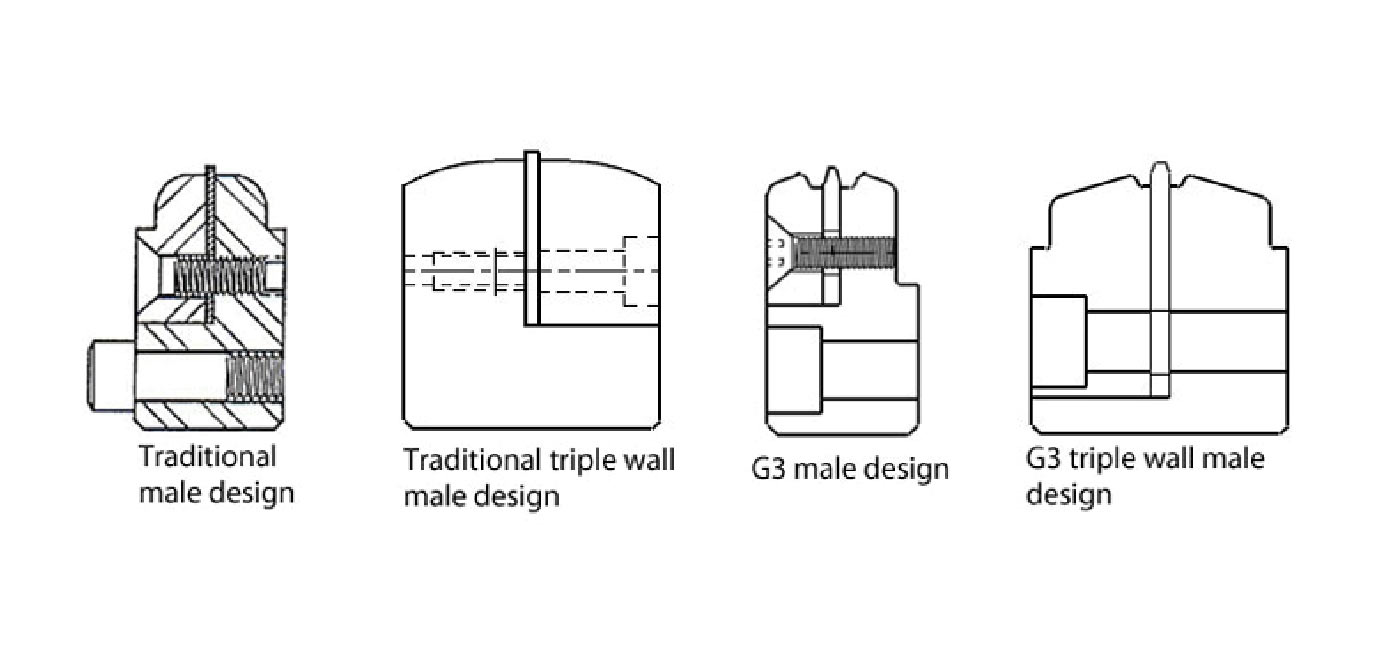

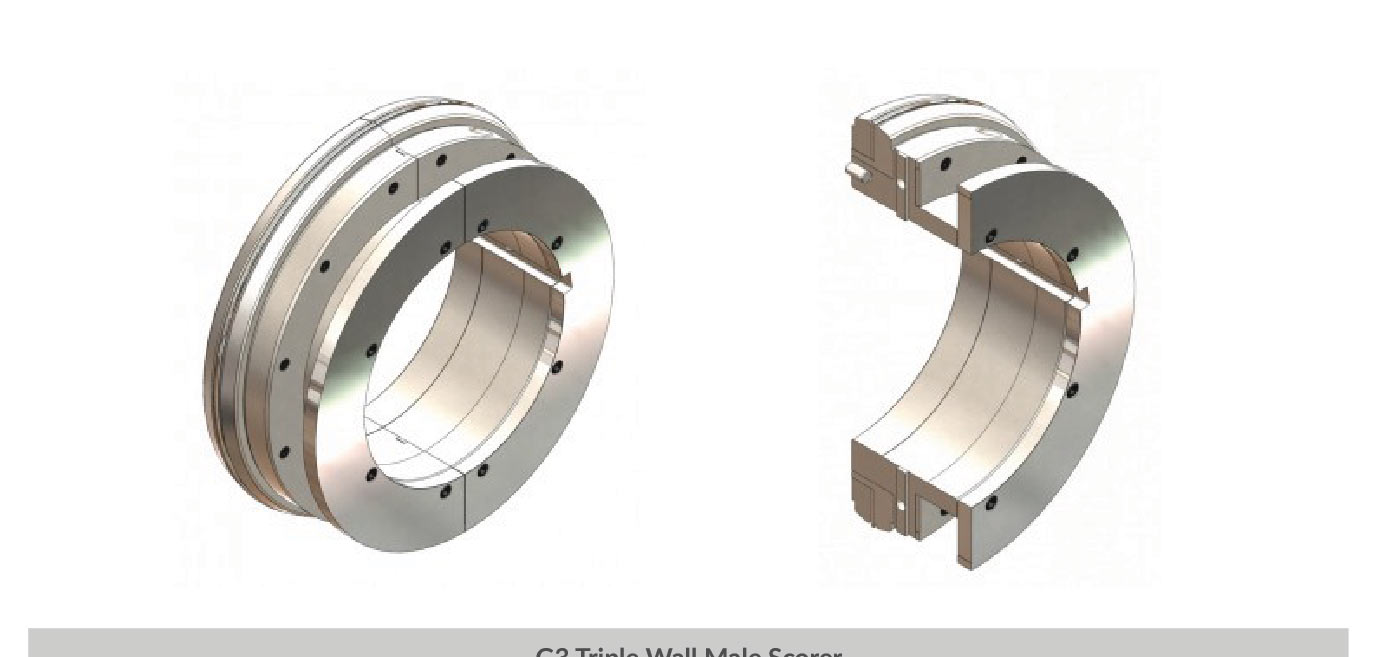

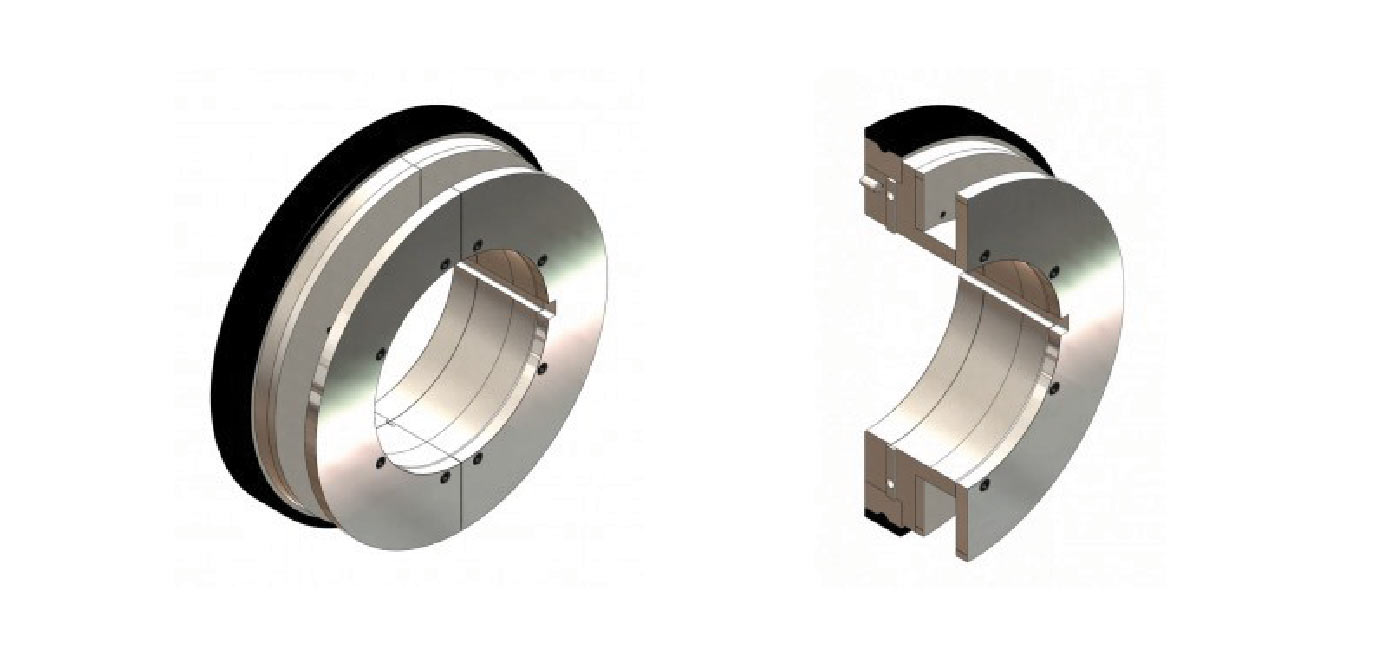

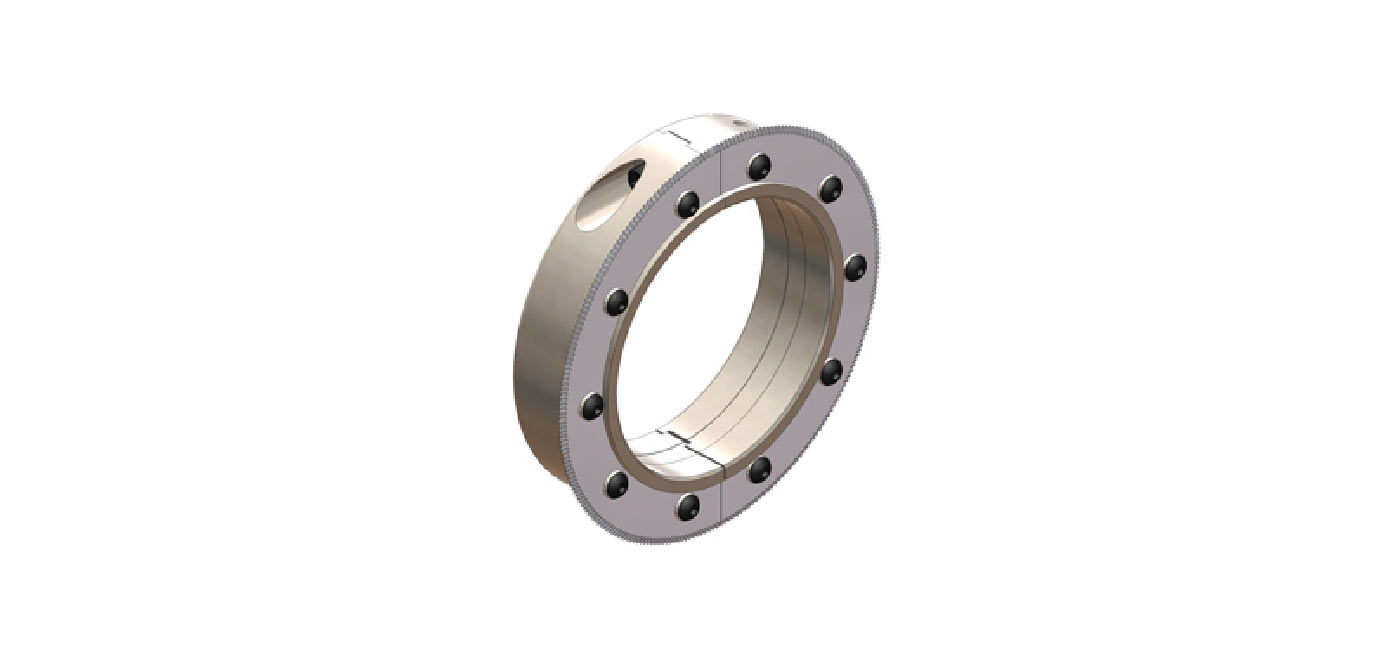

Triple Wall Creasing Heads

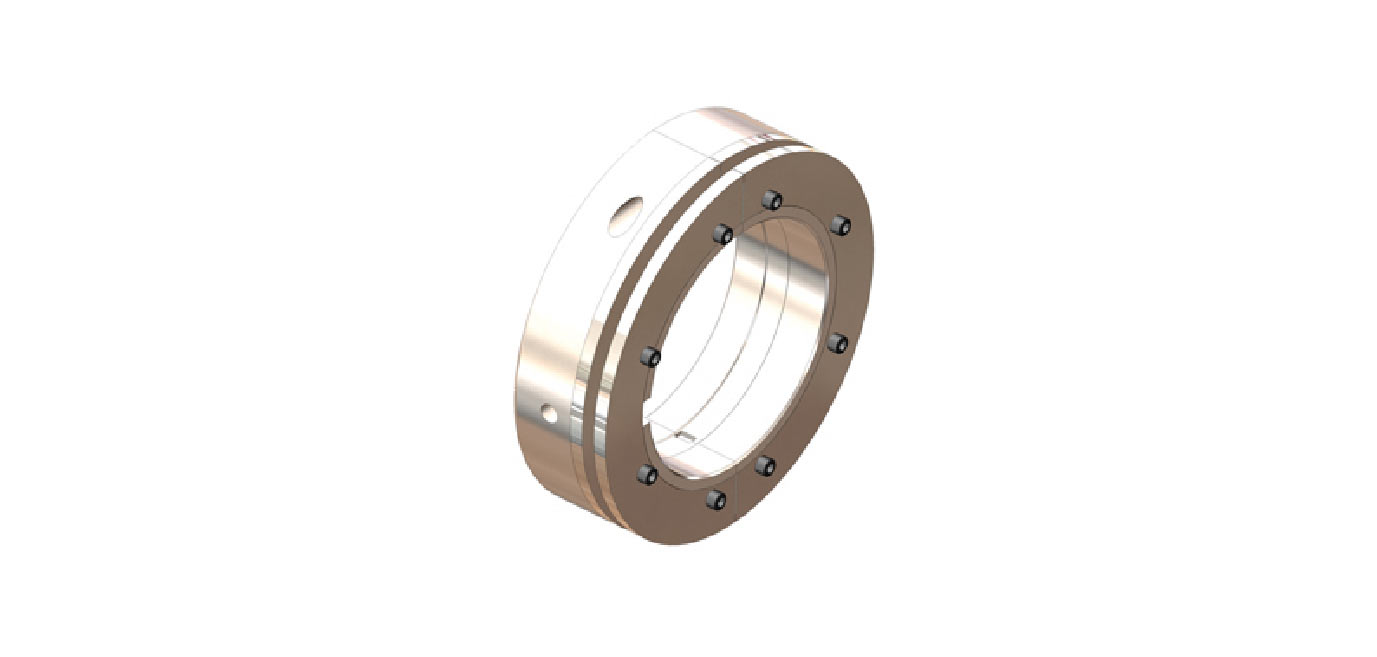

Sauer System offers creasing heads and rings for triple wall and heavy double wall applications.

Triple wall creasing heads and rings feature a significantly wider creasing profile with wider shoulders for additional crush and a wider scoring bead. Although intended for creasing triple wall and heavy duty double wall board, the creasers will work equally well on single wall and lighter grades of board. There is no need to switch out scorers when changing board thicknesses.

Both traditional and G3 triple wall creasers are available.

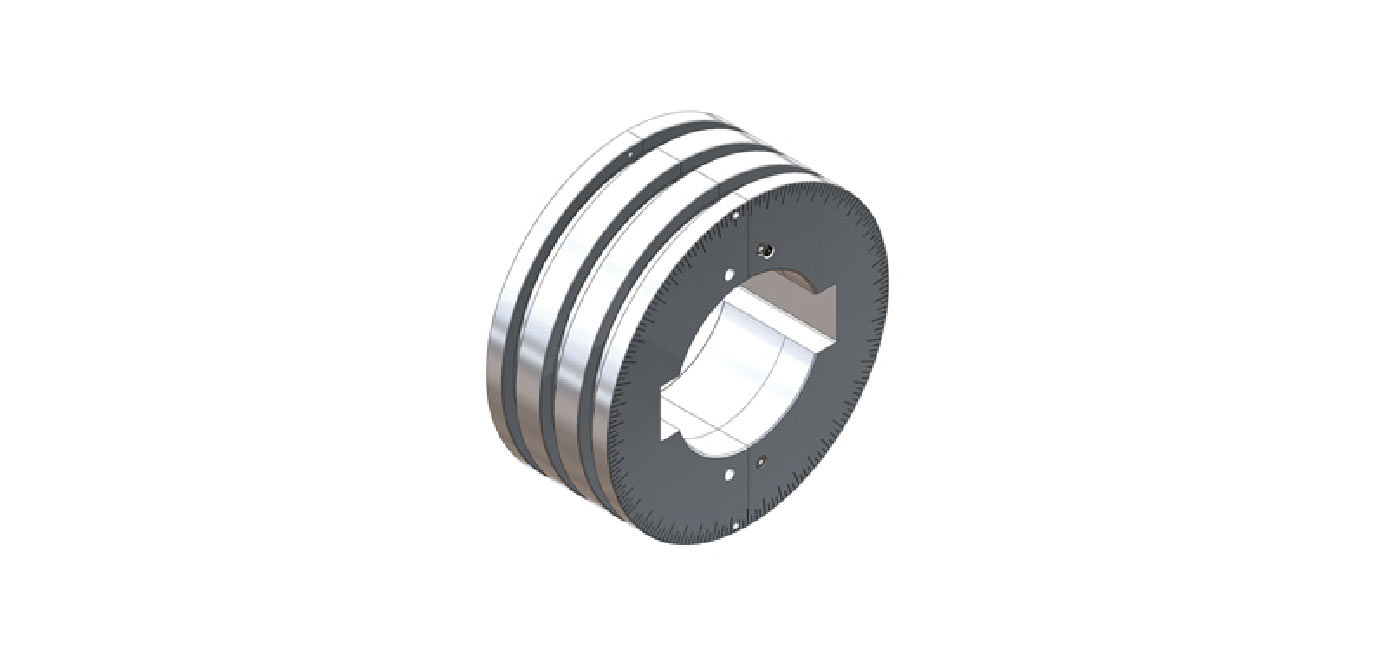

G3 Triple Wall Creasers

The G3 triple wall profile is based on the popular G3 creasing profile and utilizes the same concept: relief for the inside liner to create a more consistent fold when converting board with high recycled content.

Traditional Triple Wall Creasers

The traditional creasing profile is a wider version of the traditional Sauer System M33 scoring profile. Both the male and female profiles are 1-3/4” wide.

Crush Collars & Crusher-creasers

Customised and standard high quality replacement converting knives.

Crushing on the corrugator

For certain applications, especially those involving heavy double wall and triple wall board, crushing can be accomplished directly on the corrugator with crush collars.

Crushing on converting machines

Sauer System provides crushing heads and collars for converting machines. When it serves the application, crushers can be combined with creasers and trim knife hubs to make one complete tool.

Glue Tab Cutting Systems & Components

Sauer System pioneered a soft anvil method of glue tab cutting over 50 years ago that remains the industry standard today. When all Sauer System brand components are used together, installed, corrected and used properly, the system is designed to remove 100% of glue tabs.

Upper and Lower Glue Tab Heads

Sauer System upper glue tab heads are available in yoked and manual set designs. Each head is stamped in 1/4” increments to assist in operator set up, knurled on the outside diameter working surface, and includes t-bolt assemblies to hold tab knife holders and male slotting blades. When needed, special application requirements can be met. Examples include heads with wider shoulders for wider tab knife holders and special index stamping requirements.

Lower slot anvil systems are also furnished for yoked and manual set applications. Assemblies include the base head, pinch blade, spacer, thick blade, and anvil cover.

Both heads are made from the finest materials to prevent fatigue and include a dowel pin to ensure circular bore alignment.

Tab Knife Holders

Sauer System manufactures a wide range of tab knife holders and clamp blocks. Custom holders can be manufactured to meet special application needs. We manufacture our tab knife holders to precise dimensions to ensure proper fit on the head.

Clamp blocks are sold separately and are heat treated for longevity.

Tab Knives

A well-designed tab knife is a crucial element of successful glue tab cutting. Sauer System tab knives offer distinct design advantages and are an integral part of thes:

Knives have an angled edge notch that performs a clean pinch cut against the 3/32” blade, not a smash-and-tear operation.

The height of the beveled edge is precisely controlled

Knives have a tapered edge so they can mount against the male slotting punch without a gap

Unique 8 tooth design allows for minimal cutting pressure and precise cutting depth

Knives are fully hardened to a minimum of 40 Rc

Popular knives are conveniently packaged in kits that contain 25 left-handed and 25 right-handed knives

3/32

An integral component of effective glue tab cutting is a well designed 3/32” blade. Sauer System manufactures 3/32” blades from the finest spring steel to exacting tolerances, designed for consistent pinch-cutting of glue tabs. Our blades are designed to last longer than competitors’ blades, necessitating fewer replacements and providing greater overall value.

Soft Anvil Conversion

Steel glue tab cutting systems require a thick, expensive tab blade adjusted to make contact with a steel anvil surface. When the press operator incorrectly adjusts the pinch cut setting and applies too much pressure, the result is excessive anvil loading which transfers from the head to the shaft and gradually begins to affect the operation of the machine.

The Sauer soft anvil system is designed to eliminate the problems caused by steel glue tab cutting, protect your machine, increase operator confidence, and reduce total cost of ownership. Installing the system is quick and easy. No special tools or experience are required. Replacing tab knives, covers, and the pinch blades on a consistent basis will maintain the system. The replacement cost for these items is far less than the steel system and parts can be delivered from stock as needed. Our system is designed to provide years of trouble-free service.

Anvil Covers

Sauer System anvil covers are made from high grade polyurethane and are designed for quick installation and removal with no tools required. The unique two-piece ‘jigsaw puzzle’ design of the covers allows free-wheeling movement on the head, extending cover life.

Slotter Heads & Trim Knife Hubs

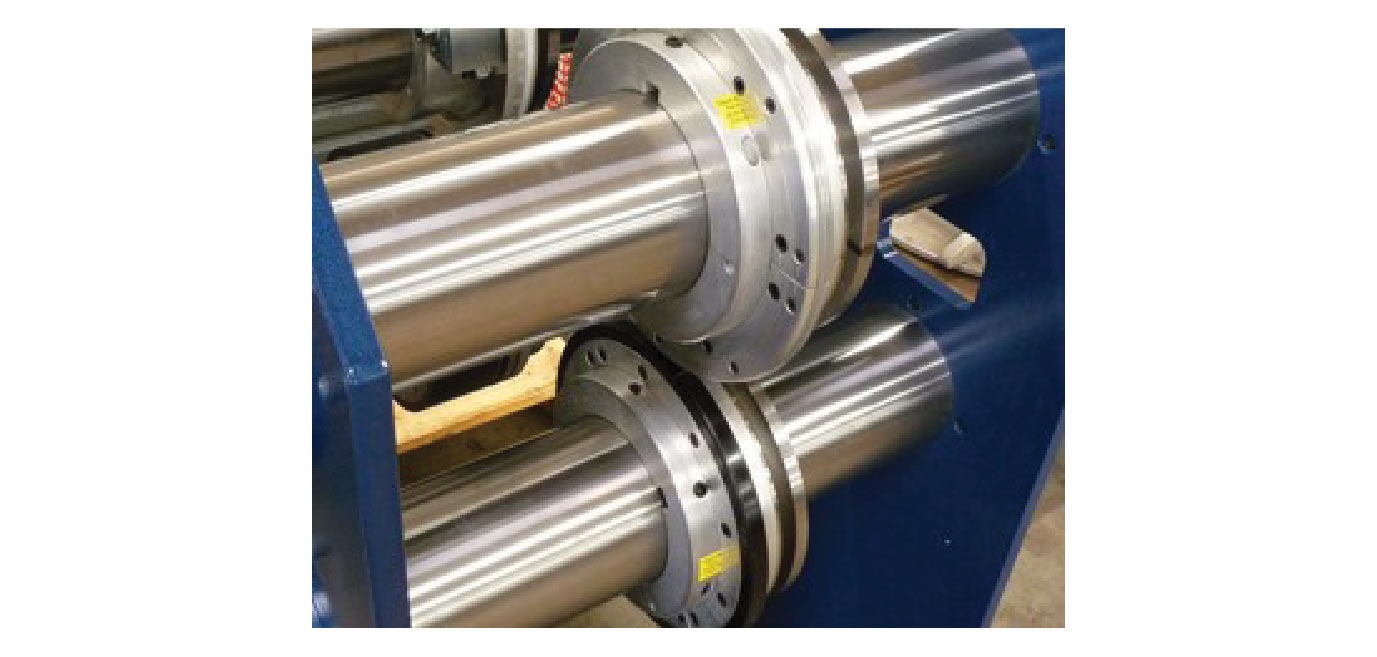

Sauer System manufactures high quality, precision machined slotter and slitter heads.

Upper and Lower Slotter Heads

Upper slotter heads are permanently index stamped, plated to prevent corrosion, and feature a dowel pin at the split line which assures perfect circular bore alignment. T-bolt assemblies are included with our slotter heads.

Lower slotter heads come as assemblies with slotting blades and a spacer when requested. Lower heads are also available without blades.

Yoked and manual set designs are both available. Where possible, yoked slotter heads can be designed as assemblies with yoke wear blades installed. Manual set slotter heads feature a brass tip assembly set-screw design which allows the operator to clamp the head in place without damaging the shaft.

Female Slotting Blades and Spacers

Sauer System’s female slotting blades and spacers are manufactured from high quality tool steel for a longer lasting cutting edge. All blades are machined true to maintain a consistent shearing surface, with special attention paid to tolerances and face run-out. The result is cleaner cutting and extended life of the knives which cut against the blades.

Slitter Hubs

Sauer System manufactures trim knife hubs for printer-slotters, flexo folder-gluers, corrugators, and floor slitters. Hubs are made from cast iron, plated the prevent corrosion, and precision machined to minimize knife runout and ensure proper slitting. A knife will only run as true as the hub to which it’s mounted.

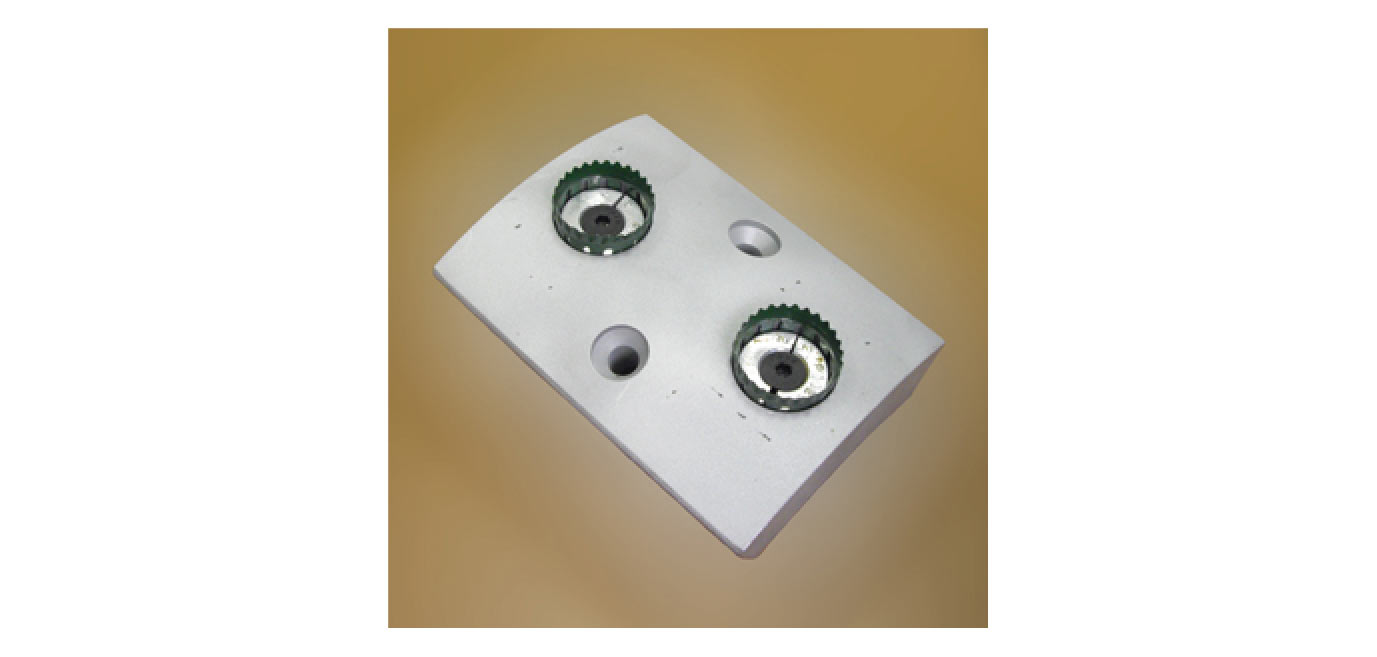

T-Slot Heads & Anvils

Sauer System T-Slot heads and anvils, known throughout the industry as “Sauer Heads” or “Sauer Attachments”, allow for a flexible system of rotary die cutting on printer-slotters and flexo folder-gluers. Common applications include hand holes, vent holes, tear tape cuts, and five panel folders. Custom designed aluminium dies are also available and T-Slot heads can also be used to hold wood dies.

Quick set-ups are assured by Sauer System’s Kam-Lok mechanism which provides easy installation, removal, and repositioning of the heads. Heads can be installed or removed in a matter of minutes and loosened for repositioning on the shaft with a quarter turn of a locking screw.

Most T-Slot heads are made from heat treated aluminium. Where weight is not a significant factor, cast iron is used. T-Slot heads are index stamped to match existing slotter heads on the shaft for quick set-up of holders.

Sauer System anvils are made from heat treated aluminium. Anvils are available in a variety of widths and can butt flush against one another to create a wider anvil surface. With combinations of anvil available, there is virtually no job limitation due to size restrictions.

Scrap Chopping System

Slitting and trimming often creates long scrap that has problems entering the waste chute and can cause numerous problems.

Sauer System scrap chop assemblies cut this scrap into small pieces that are more manageable. The system features a male hub designed to hold replaceable knives which run against a female polyurethane anvil.

Scrap chop heads can be mounted on either the slotting shaft or scoring shaft and are available in yoked and manual set designs. A variation is also available for floor slitters.

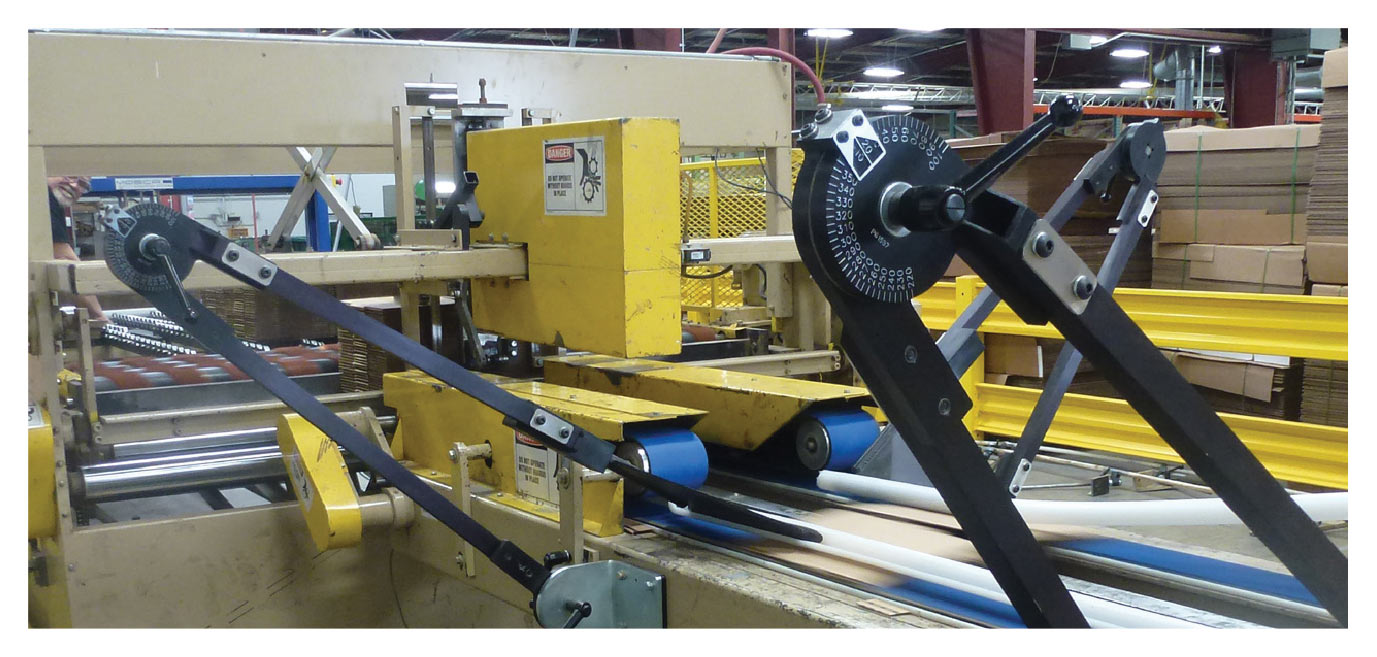

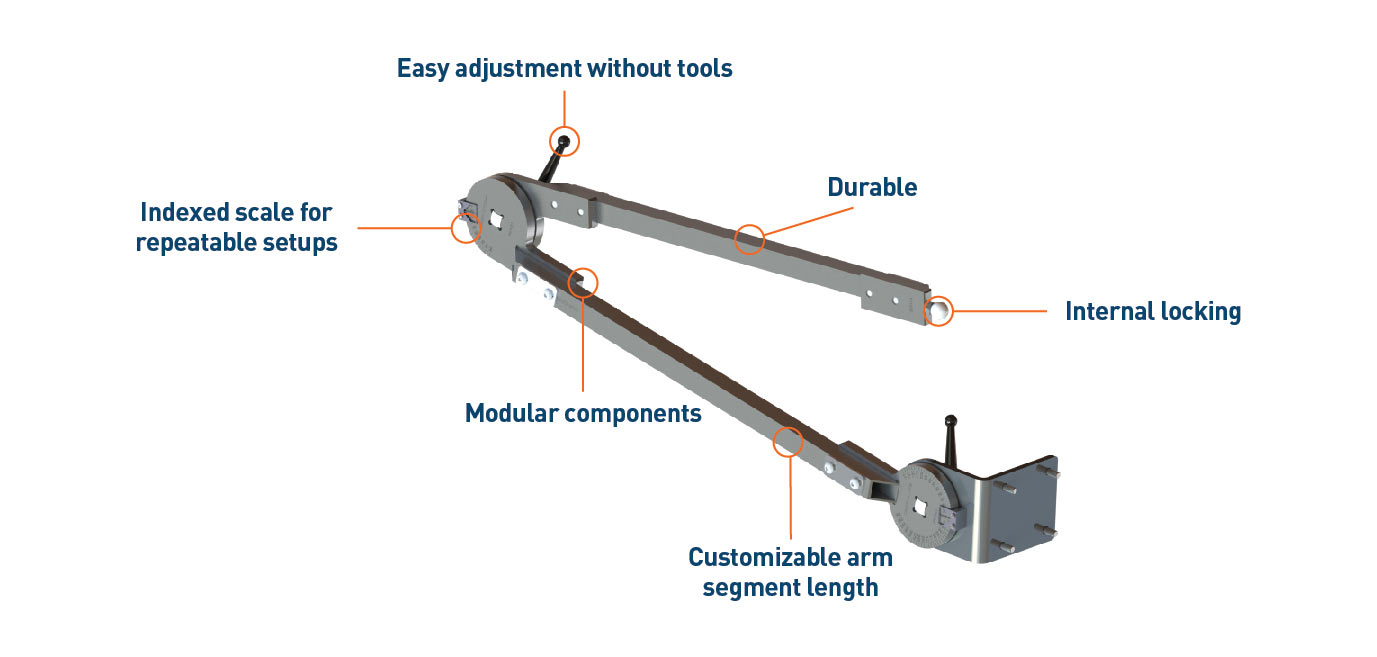

FRX Adjustable Folding Rail System

Sauer System is pleased to announce the official release of the new FRX adjustable folding rail system. The system replaces existing folding rail systems or can be added to a folding section to allow greater control of the boxes as they pass through the folder.

The arms are made from lightweight aluminium tubing and can be easily cut to a specific size. The rail is made of ultra-high-molecular-weight polyethylene, a self-lubricating, abrasion-resistant material chosen for its low coefficient of friction.

The system is designed for self-installation and features a complete installation kit and guide.

Return on investment considerations

Decreased setup time

During certain orders, the folding rods need to be adjusted for optimal folding. The FRX system features positive locking and doesn’t require the use of mallets or other tools to loosen and adjust the rods. Furthermore, the folding arms have integrated scales which allow for repeatability of setups. These features reduce operator frustration and encourage quicker and more accurate setups.

Increased machine speed

The flexible folding arms allow the folding rods to be set in exactly the right position to achieve optimal folding. This flexibility allows the machine to be run at higher speeds without compromising fold quality. In addition, the folding arms closest to the counter-ejector have elongated pennant ends that hold the boxes flat as they exit the folder.

Reduced jam-ups, waste, and machine downtime

The FRX system features an internal attachment mechanism that eliminates ‘catch points’ for boxes running through the folder. When a box becomes caught on a catch point, the machine must be stopped and improperly folded boxes must be scrapped. At higher run speeds, a serious jam-up could occur resulting in significant downtime and damage to equipment. This problem is virtually eliminated with the FRX system.

Other considerations

- Improved folding and higher quality finished cartons.

- Increased operator confidence and decreased frustration.

- Decreased chance of machine downtime.

- Easily installed by maintenance crews.

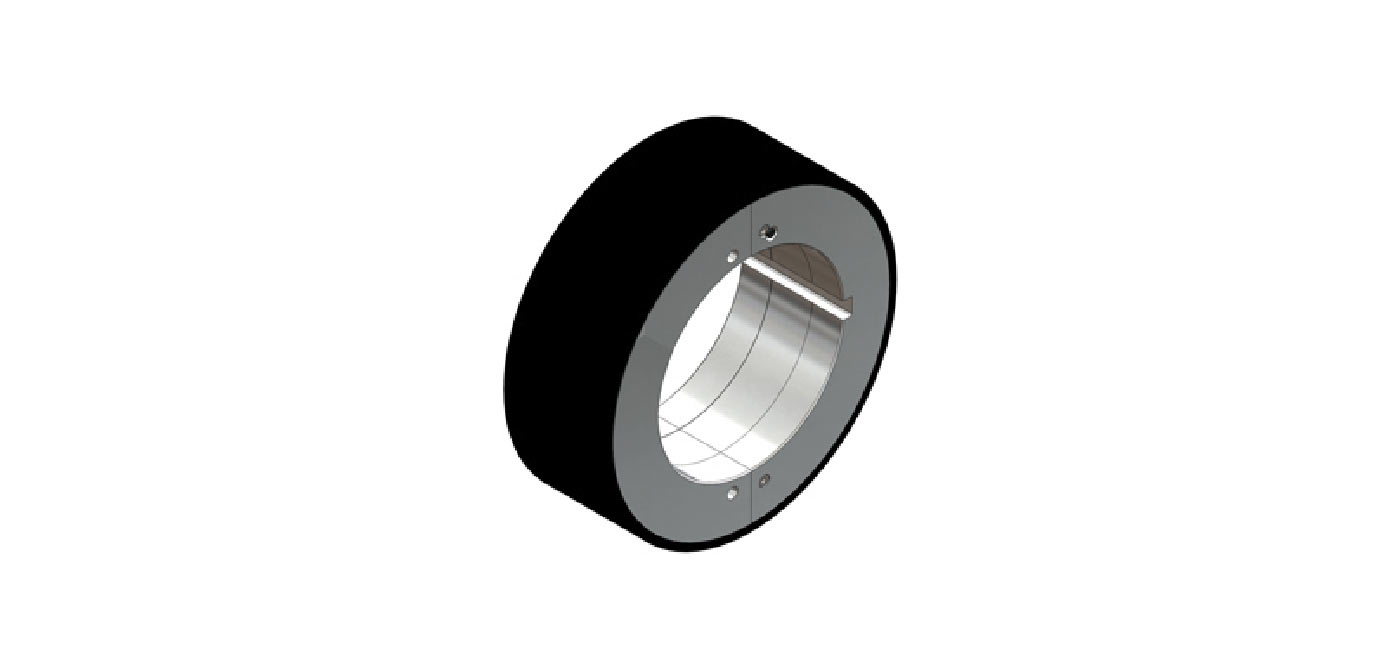

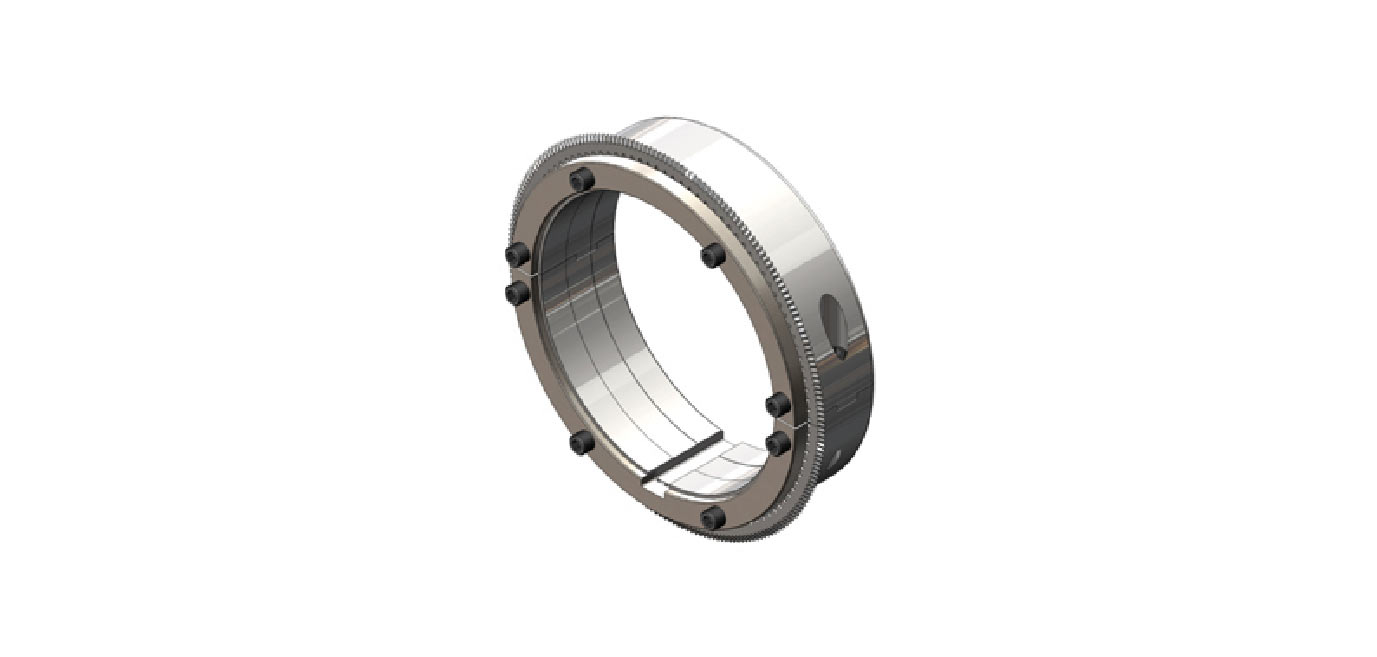

Pull Collars

Board Transfer

Sauer System offers pull collars in two main styles: for feeding and for crushing. Yoked and non-yoked styles are both available, with non-yoked collars featuring Sauer System single-screw-release clamping.

We engineer our pull collars to precise paper speed diameters to ensure proper registration. Worn or incorrectly sized collars can lead to print and slot registration problems, and skewed sheets. Our collars are made from high quality cast iron, not steel, so collars won’t stretch or gall your shaft and are plated to prevent corrosion.

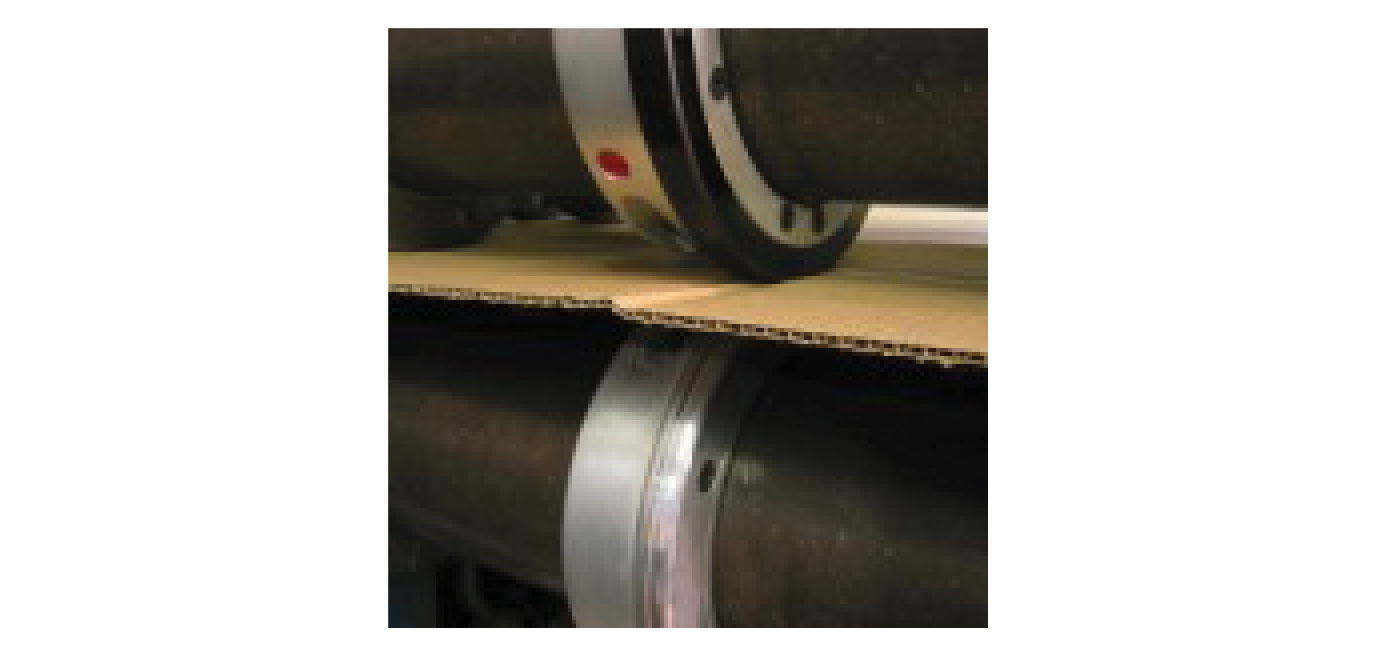

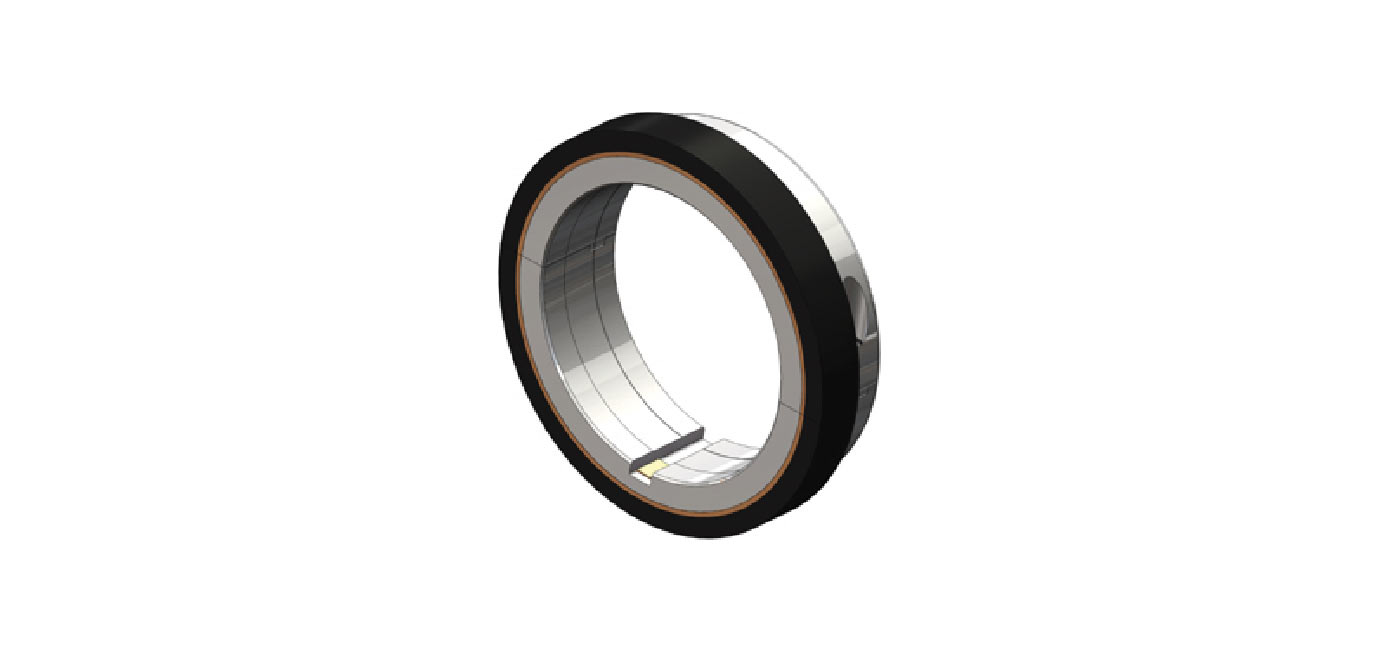

Slit-Scoring Systems

Slit‐scoring, an alternative to traditional scoring, is particularly useful for manufacturing wraps or internal packaging applications.

Slit-Scoring on the Corrugator

Slit‐scoring can be achieved on the corrugator with a slit‐score knife cutting into a free‐wheeling bronze‐ring‐backed polyurethane anvil traveling at the speed of the web.

Slit-Scoring on Converting Machines

Slit-scoring systems are also available for all types of converting machines.

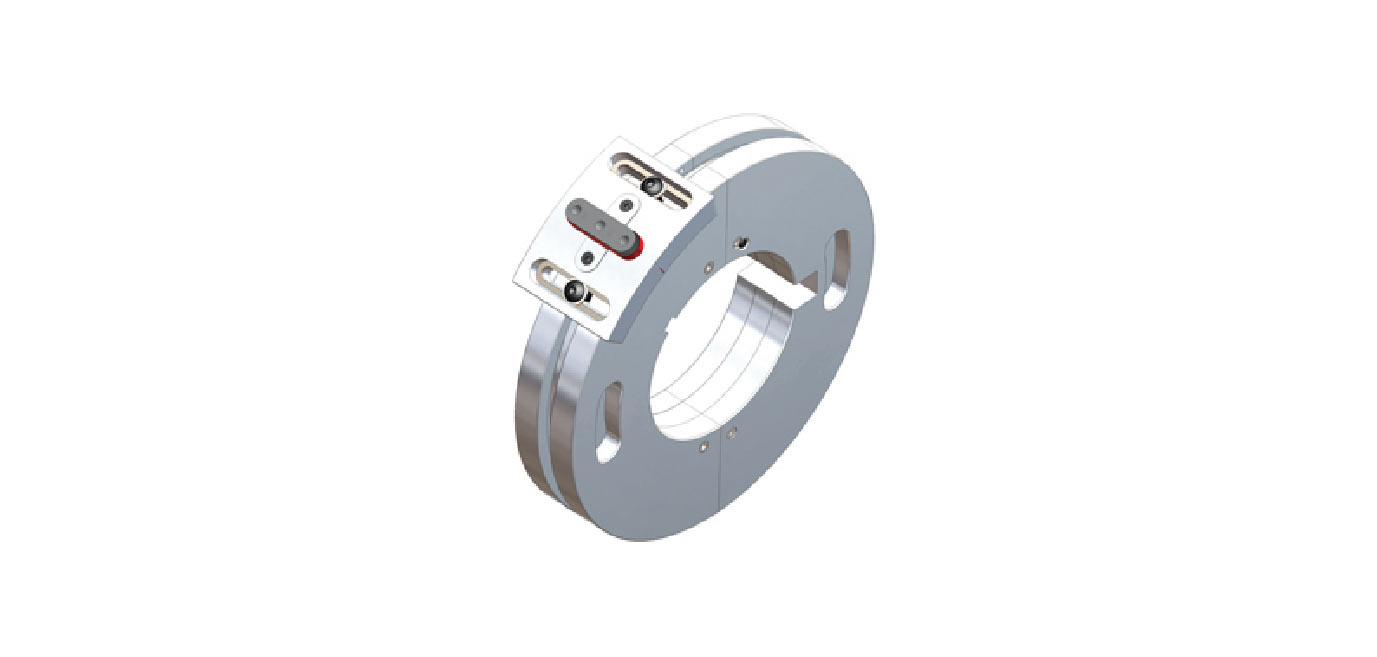

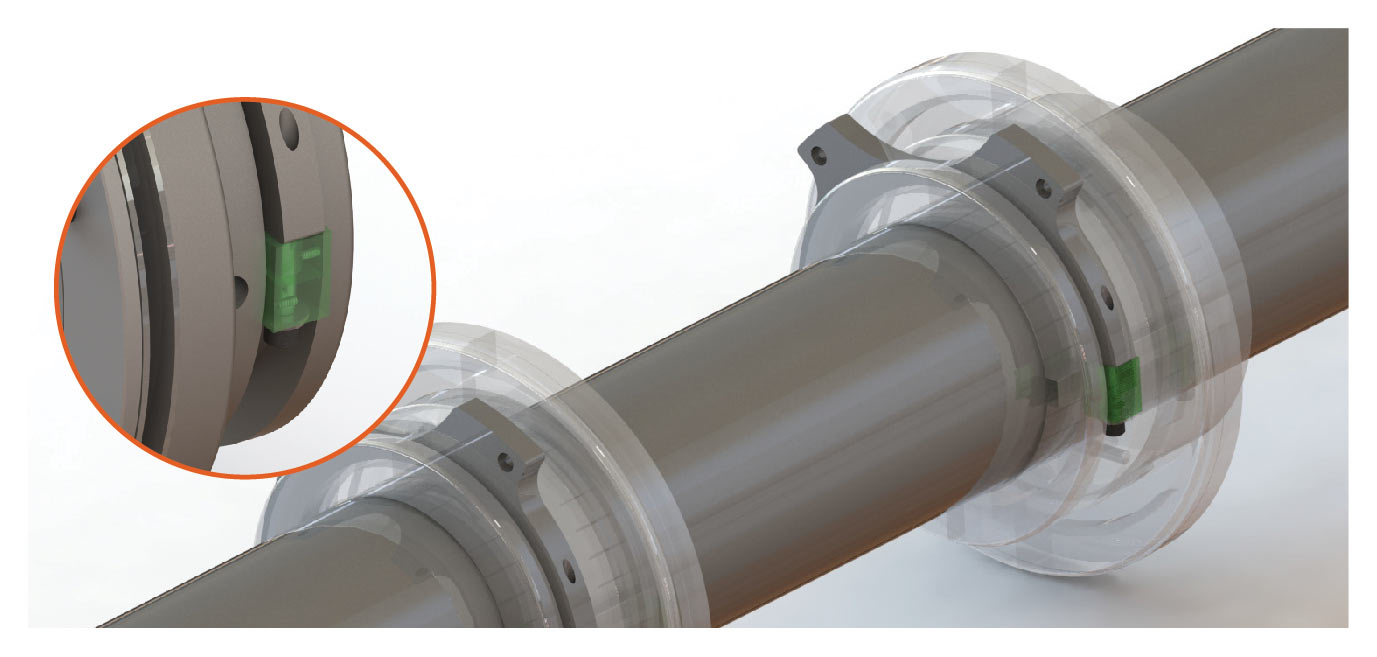

Yoke System

Accurate, on-the-fly adjustments

Instead of using a typical yoke wear plate configuration with carbon wear buttons or metal shims, Sauer have developed a yoke wear plate with a spring-loaded composite block mechanism that allows for on-the-fly adjustment of the width of the blocks. The cut-away diagram shows the internal spring. The wear blocks are held close with an end blot. When the composite block pieces wear down, you can simply loosen the bolt, and the pieces will spring out to compensate for the wear, and can then be bolted tight again. The ability to make this adjustment on the fly by simply loosening and tightening two bolts means adjustments will be made more often and will be accurate.

The Sauer Shoe System Advantage

- Longer life of heads

- Higher quality slots

- Longer life of male and female slotting knives

- Reduced maintenance and downtime

- Longer life of yoke blocks

- Adapts to heads with worn yoke grooves

- No longer needing to purchase pricey carbon or brass buttons

- Noise reduction during production

- Easy visual inspection

- Superior material characteristics

Special Applications

Specialty Profile Design

Specialty profiles including offset point‐to‐point scorers on specific centers, 5‐point, 7‐point, and 9‐point scorers can all be achieved on the corrugator. This provides the box maker with options to meet customer needs.

Unique Applications

Limited die cutting can be achieved on the corrugator as well, with the repeat of the cut being determined by the circumference of the die cutting tool and the speed of the web. Applications are limited at this time with future development opportunities pending.